What is PEX Piping?

PEX piping

(Shorthand for cross-linked polyethylene) is priced at less than half the cost of copper and can be installed significantly quicker. Due to its flexibility, PEX simplifies renovation tasks. It possesses a robust “memory,” always trying to revert to its initial form. Handling a roll of PEX feels akin to grappling with an enormous Slinky. In many cases, opting for 10-foot sections rather than rolls proves advantageous despite slightly higher costs per foot and the potential necessity of using one or two couplers. This approach minimizes hassle and prevents damage from bending too sharply. Many plumbers who regularly work with extensive lengths of PEX still prefer purchasing these shorter segments over full rolls.

Which Is Superior: PEX or Copper?

PEX offers numerous benefits compared to

copper pipes

:

-

PEX is more cost-effective compared to copper.

Half-inch PEX tubing typically costs around one-third the price of copper. A portion of these savings will be allocated for buying a specific tool needed for installing the fittings. However, if you’re undertaking a moderate-to-large scale plumbing project, you’ll generally find that using PEX instead of copper leads to overall cost savings. -

PEX connectors can be installed more quickly compared to copper.

If you opt for a manifold and ‘home-run’ setup, it functions akin to connecting a garden hose to each fixture—swift and straightforward. Even if you decide to install

PEX fittings

In a traditional mainline and branch setup, making the connections is faster compared to soldering copper. -

A PEX supply will not rust like copper.

If your location has acidic water, copper may deteriorate gradually. However, a PEX supply remains impervious to acidic water, making it a superior option for such regions.

Check out this video to discover more about the PEX revolution:

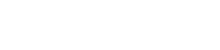

What Regarding PEX Compared to CPVC?

A

PEX supply and CPVC

cost about the same. But there are a few reasons why PEX may be a better choice. First, a PEX doesn’t require glue, which means you don’t have to work in well-ventilated spaces or wear a respirator. PEX pipe is less likely than

CPVC pipe

to burst if it freezes. Also, since PEX is more flexible and available in long lengths, it can work better for ‘fishing’ through walls in remodeling situations.

Is There a Need for Specific Tools?

Yes. When

plumbing with PEX

You can utilize either push-fit or compression fittings for these connections; however, they tend to be quite costly for extensive projects. Most PEX installation tasks necessitate specialized tools. Among various PEX connection techniques, just two options are cost-effective enough for typical do-it-yourself enthusiasts: crimp rings and pull tabs.

Crimp rings are metallic bands, typically made of copper, which you slide onto a fitting and then compact using a specialized crimping tool. The primary disadvantage is that you will require either distinct crimping tools designed specifically for half-inch and three-quarters-inch fittings or a single universal tool equipped with interchangeable inserts (which aren’t illustrated here).

Screw clamps function similarly to the conventional band clamps you might know well. To use them, slide the screw clamp mechanism onto the extending tab and press down to secure the clamp tighter. This single tool accommodates various sizes of screw clamps. We prefer the model illustrated here as it allows you to steady the ring using one hand while securing it with your other hand.

The sole additional specialized tool required is a scissor-like device for cutting the tubing.

What Steps Are Involved in Inserting PEX Fittings Into an Already Installed Pipe?

Several techniques can be employed for this purpose. The simplest approach involves cutting a segment from your water supply line and inserting a push-fit tee connector (as shown on the left side). A popular choice among these fittings would be those made under the ‘SharkBite’ label. Importantly, using such connectors does not necessitate

soldering

, which can be a big time-saver. But check with your plumbing inspector if you’re planning to bury this connection in a wall or ceiling. Some areas don’t allow stab-in fittings to be concealed. Another method is to solder in a tee and a PEX supply adapter. Then slip the PEX supply tubing over the adapter and attach it with your chosen connection method (right). You can also use a stab-in tee to connect

PEX fittings

Supply to CPVC. Check the label for compatible fittings.

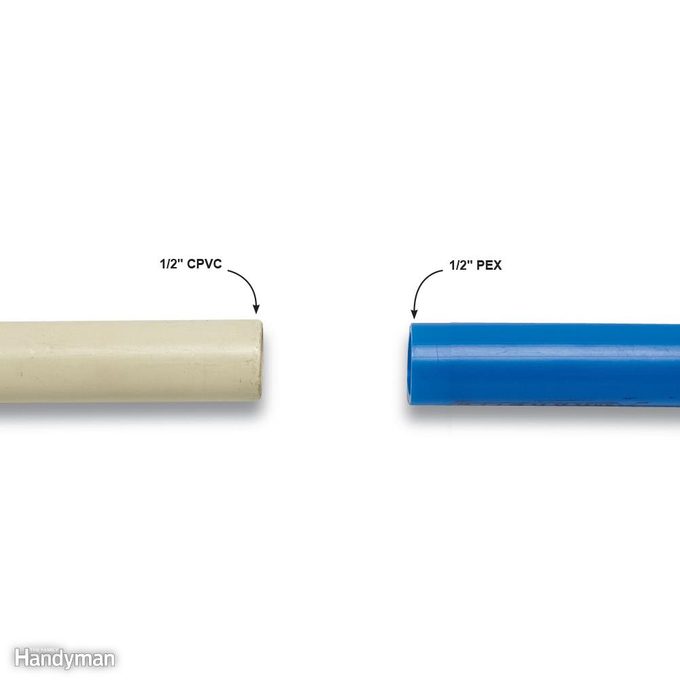

Do I Need to Utilize Manifolds with PEX?

No. Installing PEX fittings in a conventional manner—similar to how you’d work with standard pipes—is possible, using primary lines along with branch lines leading to individual fixtures. However, doing so diminishes much of what makes PEX advantageous because it necessitates numerous fittings. In contrast, adopting the home-run setup involves positioning a manifold near your utility room or close to the main water source and water heater. From here, dedicate a distinct PEX line to every single fixture as illustrated earlier. Although this method consumes additional piping material, it simplifies installation processes requiring merely two connection points per line—one linked to the manifold and the second terminating at the fixture itself. Alternatively, consider utilizing a mixed approach whereby half-inch or three-quarter inch hot and cold mains feed into a compact manifold situated typically behind walls within areas such as bathrooms.

access panel

Next, create short runs of half-inch PEX waterline tubing to each appliance.

Manifolds might seem daunting at first. However, they really make plumbing installations easier and more streamlined.

reduce possible leaks

By removing the requirement for tees and additional fittings between the primary supply line and the fixture.

Does it Meet Code?

There is no unified national plumbing code. Before starting your PEX plumbing job, check with your local inspector for specific local requirements.

Do I Have to Use Red for Hot and Blue for Cold?

PEX

comes in red and blue colors to help you keep track of the hot and cold lines. You can use white PEX for everything if you prefer.

Is PEX Reliable?

PEX has been utilized for many years in various nations, where numerous residences boast 30-year-old, leak-resistant PEX installations. The majority of issues encountered with PEX systems both within the U.S. and internationally have stemmed from poor installation practices or defective connectors instead of flaws inherent to the tubing material itself.

Is It Possible to Connect PEX to My Water Heater?

PEX cannot be directly attached to another component.

water heater

First, attach a pipe extending 18 inches from your water heater and join the PEX tubing to this pipe.

What Type of Tubing Is Suitable for Indoor Water Supply Lines?

When dealing with water lines, there are three main grades of PEX supply: PEX-A, PEX-B, and PEX-C. These varieties differ in manufacturing processes, with PEX-A offering a bit more flexibility. While shopping online, consider spending a small additional amount for PEX-A since it’s marginally superior. However, there’s no urgent need to search extensively for this specific type as the distinction is not significant. Plumbers we consulted mentioned they would be comfortable using any of these variants in their own residences. Additionally, PEX is widely used in underfloor radiant heating setups, but ensure you select PEX tubing designed with an oxygen barrier for such applications.

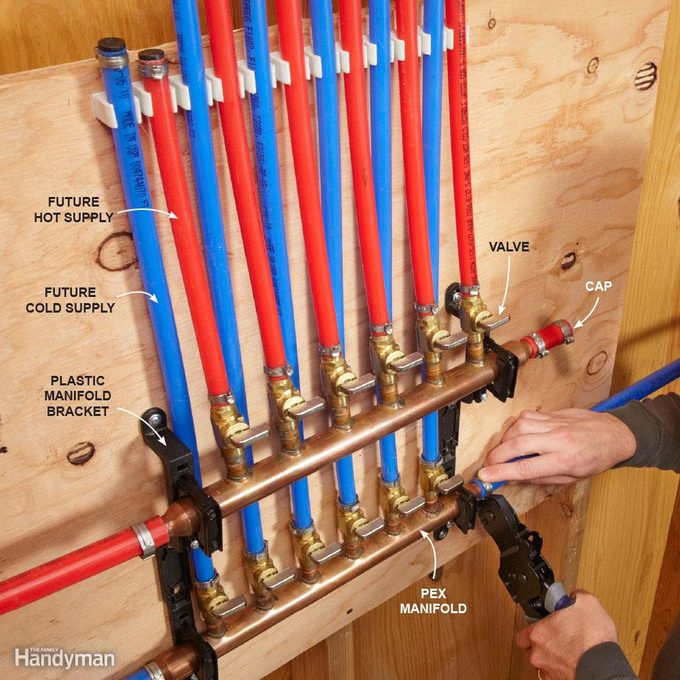

What Steps Should I Follow to Attach PEX Tubing to My Plumbing Fittings?

Several approaches can be used here. For connections that remain exposed, such as those found beneath a wall-mounted sink, opting for an aesthetic solution might involve installing a copper stub-out (as shown on the left). This allows you to attach a half-inch compression-style shut-off valve to the copper stub-out before connecting your plumbing fixture.

In locations where visibility isn’t an issue—like underneath a kitchen sink or within a vanity—you could simplify things further by routing PEX supply line right up to the shut-off valve instead of adding another fitting. To manage sharp bends effectively without causing damage to the pipe, employ a drop-ear bend support (illustrated on the right).

Various models of direct-connecting shut-off valves compatible with PEX piping systems are available too.

If you’re employing a manifold system equipped with valves, installing an additional shutoff valve at the fixture might be unnecessary. However, we suggest consulting your plumbing inspector for their opinion. In our view, it’s beneficial to include one anyway. The added expense is minimal, and it provides convenience by allowing you to turn off the water without having to go downstairs whenever repairs are necessary.

What About Expansion?

As PEX tubing has greater flexibility and expansion capabilities compared to copper, avoid pulling it taut during installation. Instead, let it have some slack between securing points. For extended lengths, incorporating a loop similar to what’s illustrated will help accommodate the material’s natural movement due to temperature changes. Additionally, this loop provides an opportunity to access extra tubing should corrections be needed later on. Moreover, because PEX shifts when expanding or contracting, ensure you bore slightly larger openings through structural members like studs or joists to facilitate smooth sliding of the tube. Furthermore, refrain from using metallic clamps; opt for plastic ones instead for attaching purposes.

Can PEX Pipe Burst or Crack When It Freezes?

Probably not. Manufacturers are reluctant to say so, but reports from the field suggest PEX can withstand freezing. You should still protect the tubing from freezing. But since it can expand and contract, it’s less likely to break than rigid piping.

What If I Make a Mistake? Can It Be Disassembled?

Certainly. There is a specific tool designed for trimming crimp rings, and you can utilize side cutters to eliminate cinch clamps. However,

rotary tool

A Dremel tool equipped with a cutoff blade is highly effective for slicing through either kind of connector (refer to the image provided). Once you have extracted the crimp ring or cinch clamp and removed the PEX line from the fitting, trim away the tube’s end to ensure a clean start for your new joint. Should the rotary instrument inadvertently harm the fitting, opt to install a replacement fitting instead of facing potential leakage issues.